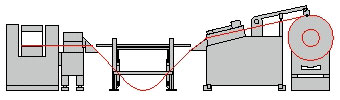

Paramount Industries is pleased to quote the CHS Automation heavy duty Coil Handling and Press feeding equipment to handle your requirements. The 3 major components are detailed below.

Model No.: DR200-42............................................................................................. Included

CHS Automation Hold Down / Threading Station

Hold Down Arm, Motorized End-Wheel, Peeler Table, De-Bending Station

Model No.: PTH-H-42 Hydraulic Operated ............................................................ Included

CHS Automation Servo Roll Feed Straightener Combination

Model No.: DRFS-642............................................................................................. Included

Package

price for the above equipment (with all included options)…….. $221,500

(FOB Truck Roseville Mi.)

Specifications For Servo Coil Line Feed

system:

Maximum coil weight...........................................................................................

20,000 Lbs

Maximum coil width...............................................................................................

42 Inches

Maximum coil outside diameter..............................................................................

72 Inches

Expansion range (T.B.D.) ..............................................................................

20 – 24 Inches

Maximum stock thickness at full width (40”

.187) ...........................................

.0.187 Inches

Minimum stock thickness...................................................................................

0.020 Inches

Recommended

Feed And Straightener Options: (additional to above cost)

Heavy

duty adjustable cabinet base + - 6”...............................................................

Included

Motorized

pass line adjustment package...............................................................

$ 5,800.00

Slide

and clamp edge guides....................................................................................

Standard

Individual

or simultaneous edge guide adjustments...............................................

$ 2,100.00

Increase

to seven straightening rolls.........................................................................

Included

Powered

pinch rolls with cluster gearing.................................................................

Included

Matte

chrome finish on upper and lower pinch rolls................................................

Included

Air

operated upper pinch roll adjustment.................................................................

Included

Remote

hand held jog pendant..................................................................................

Included

Mechanical

digital straightener settings....................................................................

Included

Automatic

release of pinch rolls on straightener when in auto feed.......................... Included

Peeler

/ Threading / De-bending station with motorized end-wheel Hydraulic ....... Included

Recommended

Reel Options: (additional to above cost)

Hydraulic

expansion.................................................................................................

Included

AC

Variable frequency drive package......................................................................

Included

Space

saver loop control (Laser-PLC).....................................................................

Included

Coil

load car model LC-200 (with anti tip arms)................................................

$ 22,800.00

Fused

disconnect......................................................................................................

Included

Clock

spring guard on back side of coil reel............................................................

Included

CHS Automation Single End AC Driven True Centering Reel

Model No DR-200-42

Specifications:

Maximum

coil weight...........................................................................................

20,000 lbs

Maximum

coil width...............................................................................................

42 Inches

Maximum

coil diameter..........................................................................................

72 Inches

Expansion

range..................................................................................

19.375” – 24.5 Inches

Voltage

at controls...........................................................................................................

110

Loading is a simple procedure. Coil reel support arms contract for ease of loading and expending in the coil ID automatically centering the coil and holding in balance. Expansion and contraction is accomplished through a hydraulic cylinder and draw bar arrangement. Control is from push buttons. The support arms will have adjustable keepers for mounting on both sides of the coil to prevent the stock from shifting off center. Coil width indicator scales (optional) are recessed in the reel arms to provide visual reference for stock width location.

OD Laser Sensor For Proportional Increase Of Rotation Rate From OD To ID

A laser sensor is mounted in the clock spring guard which increases rotation rate proportionally as the coil O.D. diminishes this feature maintains a more consistent F.P.M. rate of stock from coil O.D. to coil I.D. The reel will rotate until the material covers the electric eye switch which will stop reel rotation. Operator guard back plate is provided to keep the operator from possible inadvertent contact with the rotating arbor assembly.

CHS Automation coil reels are built of heavy duty construction. We use only brand name components, i.e.; Allen-Bradley, Vickers, Coil-Tek, Banners, Timken, Eaton, Rexroth, and many others.

| STANDARD FEATURES |

OPTIONAL FEATURES |

Model No.: PTH-H-42

The

heavy duty motorized down roll, peeler threader station is mounted on the entry side of

the feeder-straightener. An adjustable

hydraulically operated coil hold down roll is operated through the hand jog control on the

reel. The hold down roll prevents the coil

from having tendency to clock spring. The

motorized coil restrictor facilitates power threading and aids in rewind operations by

providing a tight coil wrap.

The

peeler extends or retracts to the coil O.D. by means of pneumatic cylinder. This unit is used as an aid for threading stock

into the powered straightener. Control is

from push buttons.

The

threader table raises and lowers to the proper angle to support the material from the coil

reel to straightener entry.

The lead edge may be de-bent by raising the peeler table (point retracted) to bend material between the peeler table and the de-bender assembly which is mounted on the underside of the hold down arm. The hold down wheel and the peeler table are reinforced for the purpose.

Model No.: DRFS-642

Model No.: DRFS-642

Specifications:

Feed

capacity thru straightener in mild steel

Maximum

material thickness at full width..........................................................

0.187 Inches

Maximum

material width........................................................................................

42 Inches

Feed

rolls 6 inch diameter x 43 5/8 inches long.

Feed length capability of 0 to 999.999 inches with feed. Feed length settings are controlled thru operator HMI on the control console.

User

requirements:

Roll

position accuracy to within +/- .005

Feed drive motor with full digital control.

¦ Matte

chrome finished full width feed rolls

¦

Anti-friction lifetime bearings

¦

Safety guards / deflector to insure stock path

¦ Upper

and lower feed rolls driven via cluster gearing maximizes contact

¦ Roll

release provided by pneumatic cylinders actuated by selector switch

¦ Pilot

pin release feature

¦ Air

pressure regulator w/gauge for roll pressure adjustment

¦ Dual

tie bar construction for fail safe assembly and rigidity

¦ Lower

roll driven via hollow shaft precision gear head drive

¦ Entry

vertical edge guides, slide and clamp type

¦ Right

angle press attach bracket

¦ Floor

mounted control console (slope front) with fused disconnect

¦ AC

brushless servo motor with full digital control

¦ Remote jog pendant with forward and reverse

Standard Servo Feed Control

Features(INDRAMAT)

Master control start and stop |

Speed adjust / feed length adjust |

Drive motor start and stop |

Emergency stop button |

Manual / auto selection |

Feed rolls open-close selector switch |

Hand held jog control (forward and

reverse) |

Jog forward / reverse |

Pilot pin release On / Off |

Self diagnostics |

999 Job storage memory |

On the fly micro adjust via +/- keystroke |

Input and output status displays |

Each job may have independent max speed,

length, accel, decel, and jerk settings |

Batch count capability |

Error

history log |

Password

protected control |

inch or

metric programming |

The straightener is mounted behind the

feed so that the position of the straightener always remains the same. Seven hardened and ground ball bearing rollers are

mounted so the stock is flexed between them. The

lower rolls are fixed in position. The upper rolls are adjustable through a hand crank via

heavy duty screw jacks.

A

set of powered pinch rolls are mounted on the entry side of the straightener. The lower roll is operated through a motor and

hand operated clutch. As the clutch is

engaged, the material is power driven through the straightener, feed bed and into the die

area. As the clutch is disengaged the rolls

are free turning.

Air cylinders for quick opening pinch rolls allow the operator to clamp and release pinch rolls through a hand valve which actuates two air cylinders on the upper pinch roll.

Hand Held Jog Control (Included) Jog forward and jog reverse allows rotation for threading operations at a factory preset rate of 2.5 R.P.M.

Package

price for the above equipment (with all included options)…….. $221,500

(FOB Truck Roseville Mi.)

Start-Up Assistance and training (Optional) - Call for start up rates and cost for on site installation and start up services

|

Coil and Press feed system--A versatile system designed for handling a wide range of material widths and thicknesses. The coil load car provides efficient coil loading. The combination hold down wheel/peeler/threader end debender and exit thread table allow one operator to power thread material from the reel to roll feed entry. |

STANDARD

FEATURES STANDARD

FEATURES

|

OPTIONAL FEATURES (FEED)

OPTIONAL FEATURES (STRAIGHTENER)

|

| Control Panel |

BTV04 Interface  Indramat Servo Drives |

CHS Automation

Electrical Panel: Rexroth-Indramat BTV04 operating system is standard on all CHS Automation Servo Roll Feeds. Other operating systems available upon request. STANDARD FEATURES:

|